What makes a croissant airy or a puff pastry crisp? The answer is not only in the recipe but also in the technology. The laminator, often overlooked, is the key machine that turns ordinary dough into extraordinary pastry. By mastering the process of layering dough and fat, it helps bakeries achieve the signature flakiness, texture, and appearance that define laminated products. In modern production, choosing a reliable laminator is essential for achieving these results consistently.

|

|

|

|

|

|

The working principle of the laminator is to repeatedly sheet and fold the dough while layering fat, such as butter or margarine, in between. This process is known as lamination. During operation, the dough undergoes continuous folding and rolling, creating alternating layers of dough and fat, and is gradually sheeted to the required thickness. This cycle is repeated until the desired number of layers is achieved. Different products require different numbers of layers: puff pastry often needs dozens of layers, while croissants use fewer but equally precise layers. With advanced design, our laminator ensures stable and accurate control of both thickness and layer count, guaranteeing consistent quality in every batch.

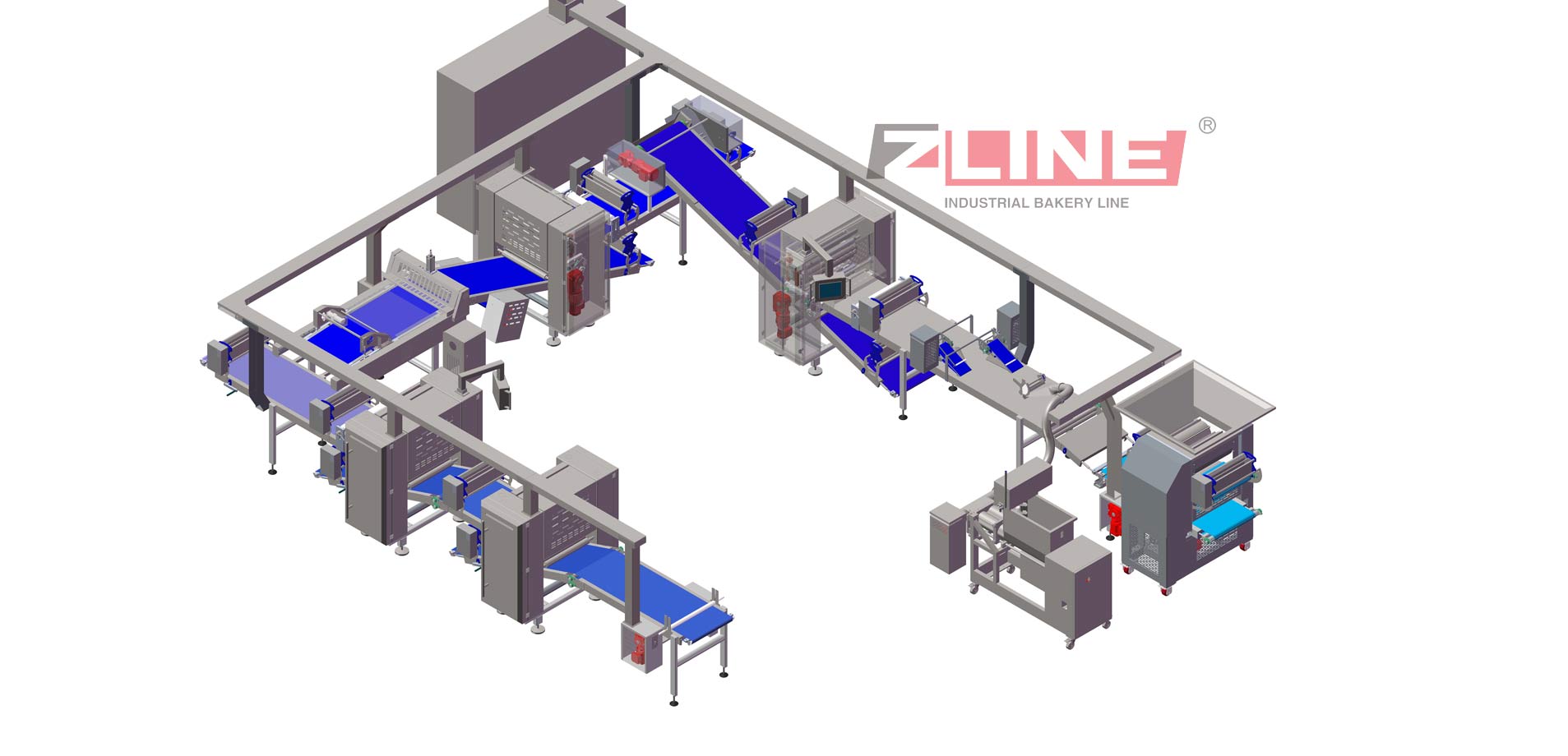

To support industrial bakeries, ZLINE’s laminator offers a processing capacity of 300–1500 kg/h (customizable according to production needs). All major components are made of SUS304 food-grade stainless steel, ensuring durability, food safety, and easy cleaning. When paired with a fully automated sheeting and pastry make-up line, the laminator forms a complete system that is easy to operate, highly efficient, and stable in performance. The lamination section provides precise control of dough sheet thickness and accurate layer management, ensuring uniform internal structure and consistent product quality after baking.

The importance of the laminator lies in its ability to deliver consistent quality at an industrial scale. Uniform layering directly determines how evenly the dough rises in the oven, creating the delicate flakes and airy texture that consumers expect. With advanced design and reliable performance, ZLINE’s laminator guarantees stable results batch after batch, while automation reduces labor costs and eliminates the inefficiencies of manual lamination. Built with flexibility in mind, the machine allows fine adjustments of thickness and layer count, making it possible to produce a wide variety of laminated pastries within the same production line. This versatility gives bakeries the confidence to respond quickly to market demands while maintaining high efficiency and consistent quality.

In conclusion, the laminator is not just a supporting tool but a cornerstone of modern pastry production. The ZLINE Laminator features core attributes of precision, efficiency, and adaptability, it enables bakeries to consistently produce pastries that meet the highest quality standards. These attributes are fully embodied in the ZLINE Laminator and related pastry production lines, helping bakeries achieve both high productivity and excellent product quality. Without such equipment, large-scale bakeries would struggle to maintain the same level of consistency and competitiveness, making the laminator an indispensable component in today’s baking industry.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)