Few things delight customers more than biting into a pastry filled with juicy raisins or crunchy nuts. These ingredients transform ordinary Danish pastry into something memorable, adding flavor, texture, and nutrition. For bakeries operating with automated lines, the challenge lies in incorporating these ingredients efficiently while ensuring consistent quality.

Adding ingredients like raisins and nuts in an automatic production environment requires careful consideration of both technology and process flow. Unlike flour, water, or butter, these ingredients are irregular in shape and texture, making them more challenging to handle. If not managed properly, they can damage the dough structure, clog equipment, or result in uneven distribution. Therefore, specialized solutions are integrated into the production line to ensure smooth operation.

|

|

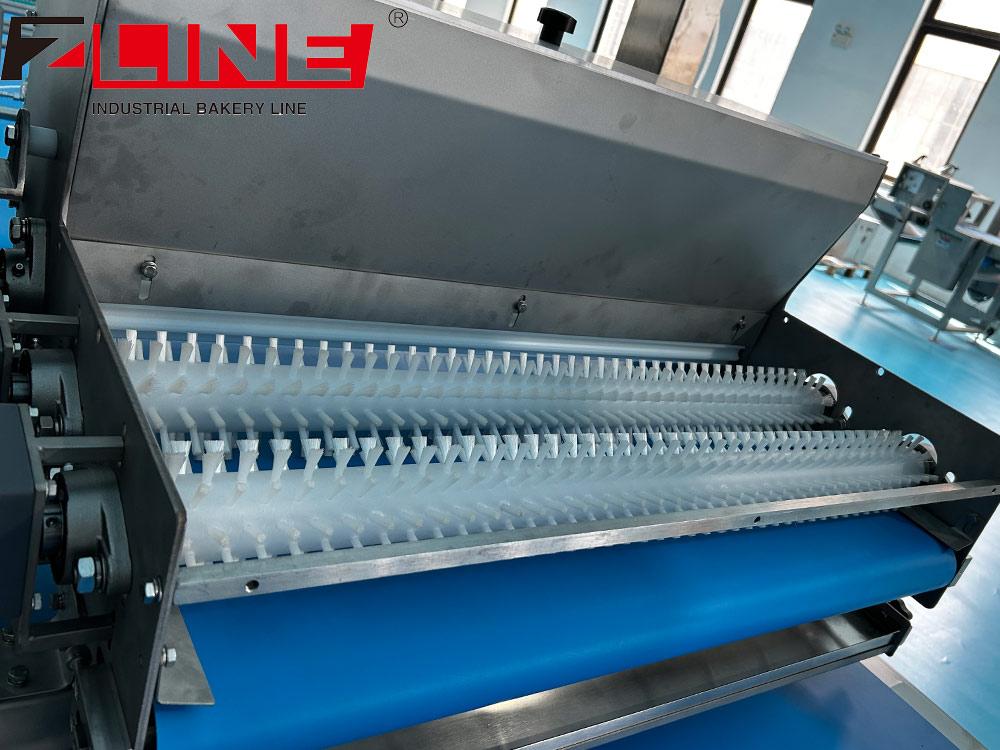

One of the most common methods is the use of a dedicated ingredient spreading machine. This unit is designed to release raisins, nuts, or similar ingredients at controlled intervals directly onto the dough sheet or into the mixer. By regulating the speed and quantity, the system guarantees uniform distribution without overloading any section of the dough. Gentle handling is essential here, as crushing the ingredients would not only compromise appearance but also alter flavor and texture.

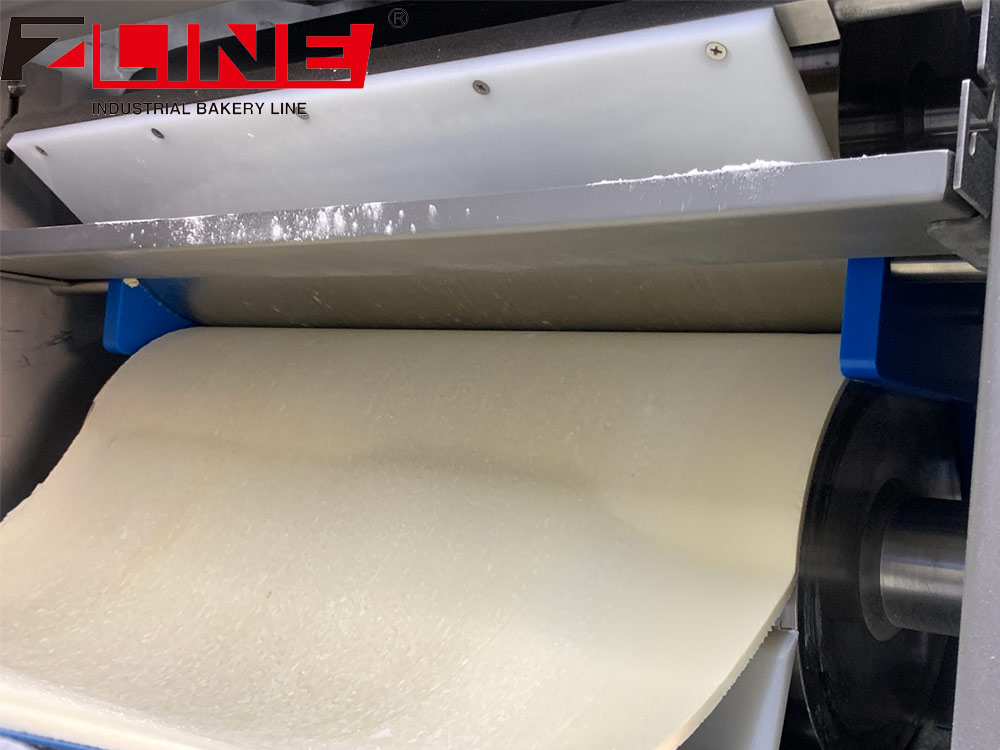

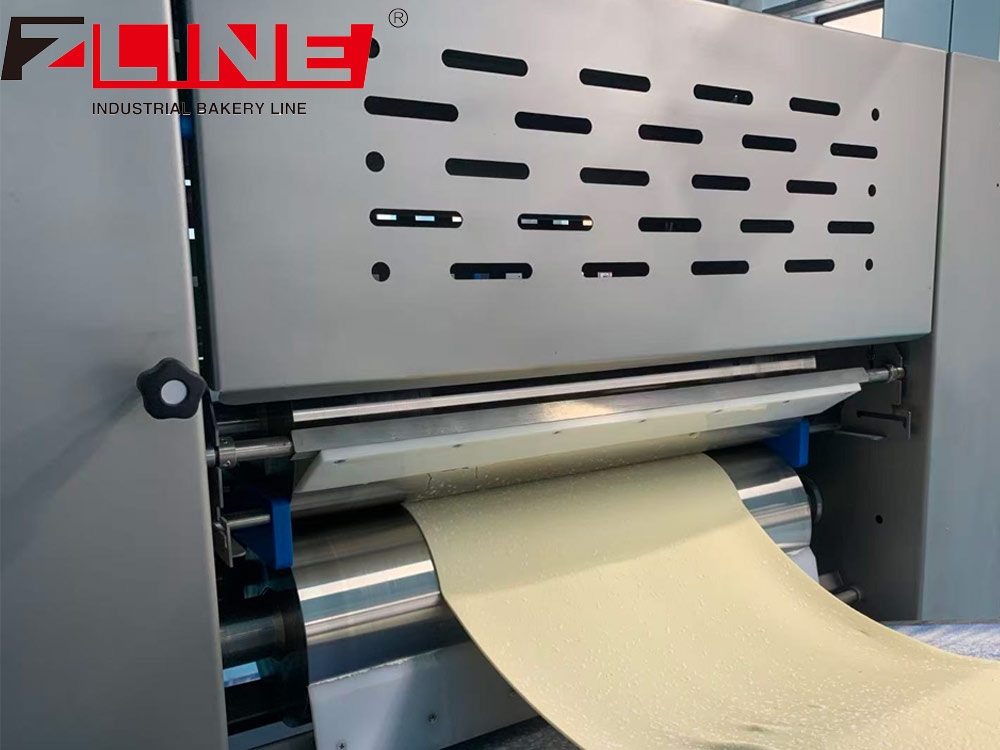

Another approach is lamination-based inclusion. In this method, the dough sheet is partially rolled out before a layer of ingredients is sprinkled evenly across the surface. The dough is then folded and laminated, embedding the ingredients throughout the layers. This process is particularly effective for Danish pastry, as it preserves the flakiness while ensuring that raisins or nuts are spread consistently in every bite. Additionally, modern lamination lines are equipped with flour dusting and alignment controls to prevent sticking and ensure the dough maintains its structural integrity.

|

|

Cleaning and hygiene are also critical factors. Ingredients like nuts can introduce allergens, while raisins may contain natural sugars that stick to machine parts. To address these challenges, production lines are designed with quick-change modules and easy-to-clean surfaces. This ensures fast switchover between recipes while minimizing the risk of cross-contamination, which is especially important for bakeries producing a wide range of products.

Finally, flexibility is the defining advantage of today’s automatic lines. With programmable logic control (PLC) systems, operators can adjust inclusion rates, timing, and distribution patterns with just a few settings. This allows bakeries to experiment with recipes, producing multiple variations such as raisin-filled Danish, nut-topped rolls, or even combinations like almond-raisin pastry—all on the same line.

|

|

|

|

In conclusion, adding ingredients such as raisins and nuts to Danish pastry bread is no longer a manual challenge but a streamlined process supported by modern automation. Through advanced ingredient spreading machines, lamination techniques, and smart control systems, bakeries can deliver creative, flavorful products at scale while preserving consistency and quality. The result is a production line that not only meets but also expands consumer expectations, giving bakeries a competitive edge in today’s diverse marketplace.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)